Answer

Oct 22, 2024 - 01:19 PM

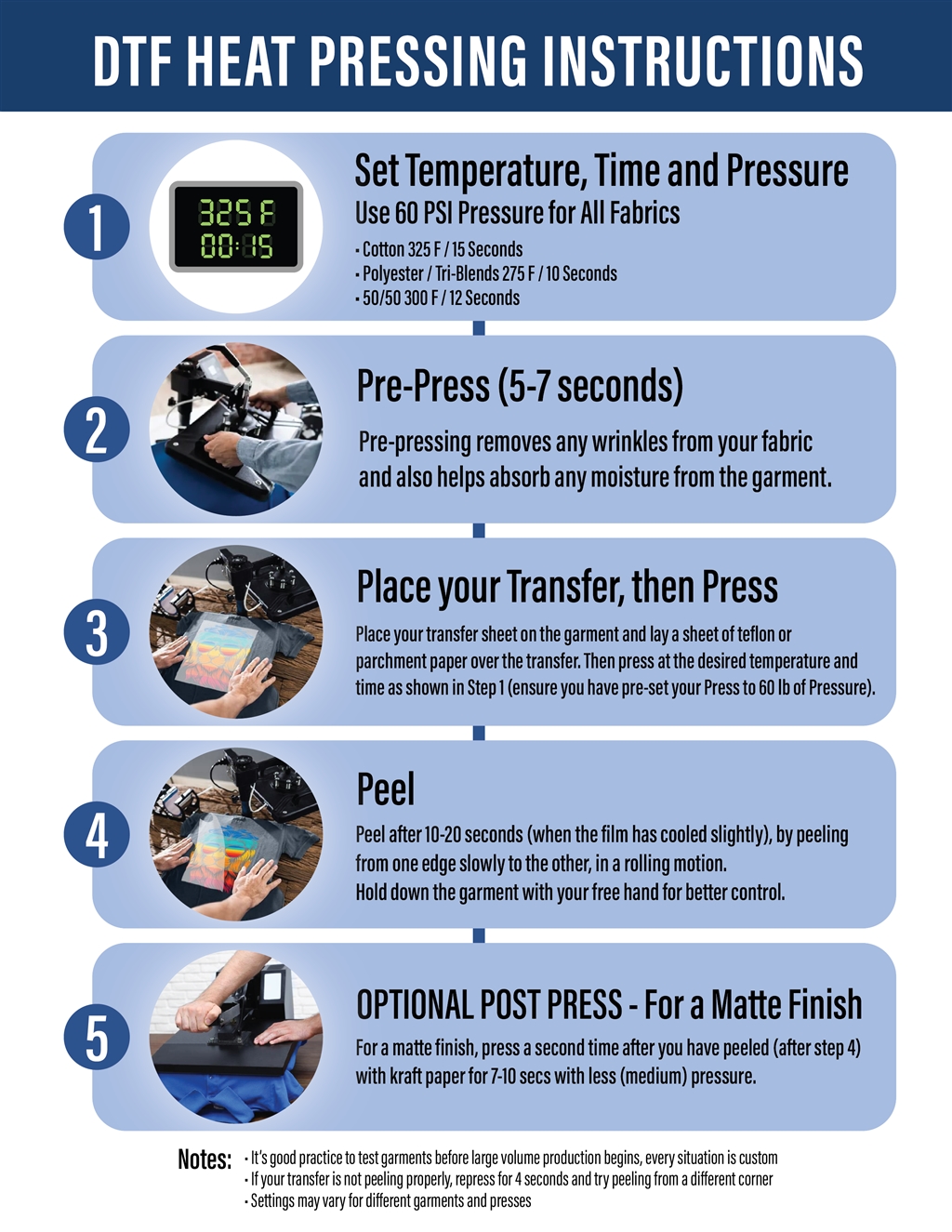

Ensure your fabric surface is thoroughly cleaned and dried before application, and adhere to the manufacturer's guidelines for temperature and pressure settings for the heat press transfer stage. Insufficient (or too much) heat or pressure during the heat press process may prevent the design from adhering properly during transfer. Additionally, ensure even pressure distribution and precise timing to guarantee optimal results on any fabric type. Optimal settings will vary depending on the type of DTF film you are using and based on the Heat Press you are using, and will also depend on the type of ink and powder you are using, but these are some generally good suggestions for starting points to consider:

For Cotton: 300 F / 15 Sec

For Polyester or Tri-Blends: 275 F / 10 Sec

For 50/50 Cotton/Poly Blends: 300 F / 12 Sec

Use 60 PSI Pressure on all fabric types.

See below instruction guide for the entire DTF transfer process.

A post-press is highly recommended, and although this can be done with Kraft or Parchment Paper, for the ultimate in wash-fastness, durability and stretch-ability of your DTF-created apparel, post press your transfer with the DTFPRO MagicSeal.