Answer

Oct 22, 2024 - 01:29 PM

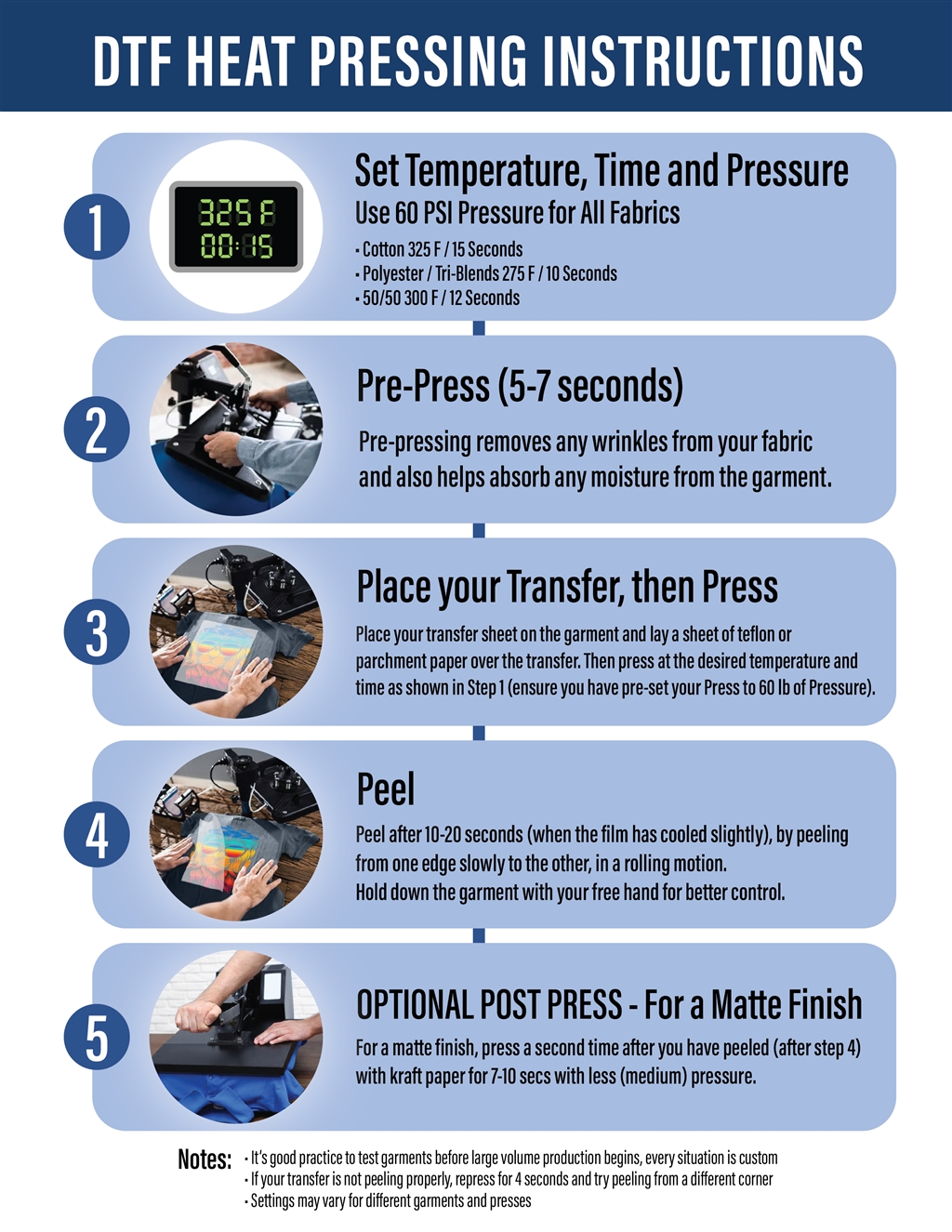

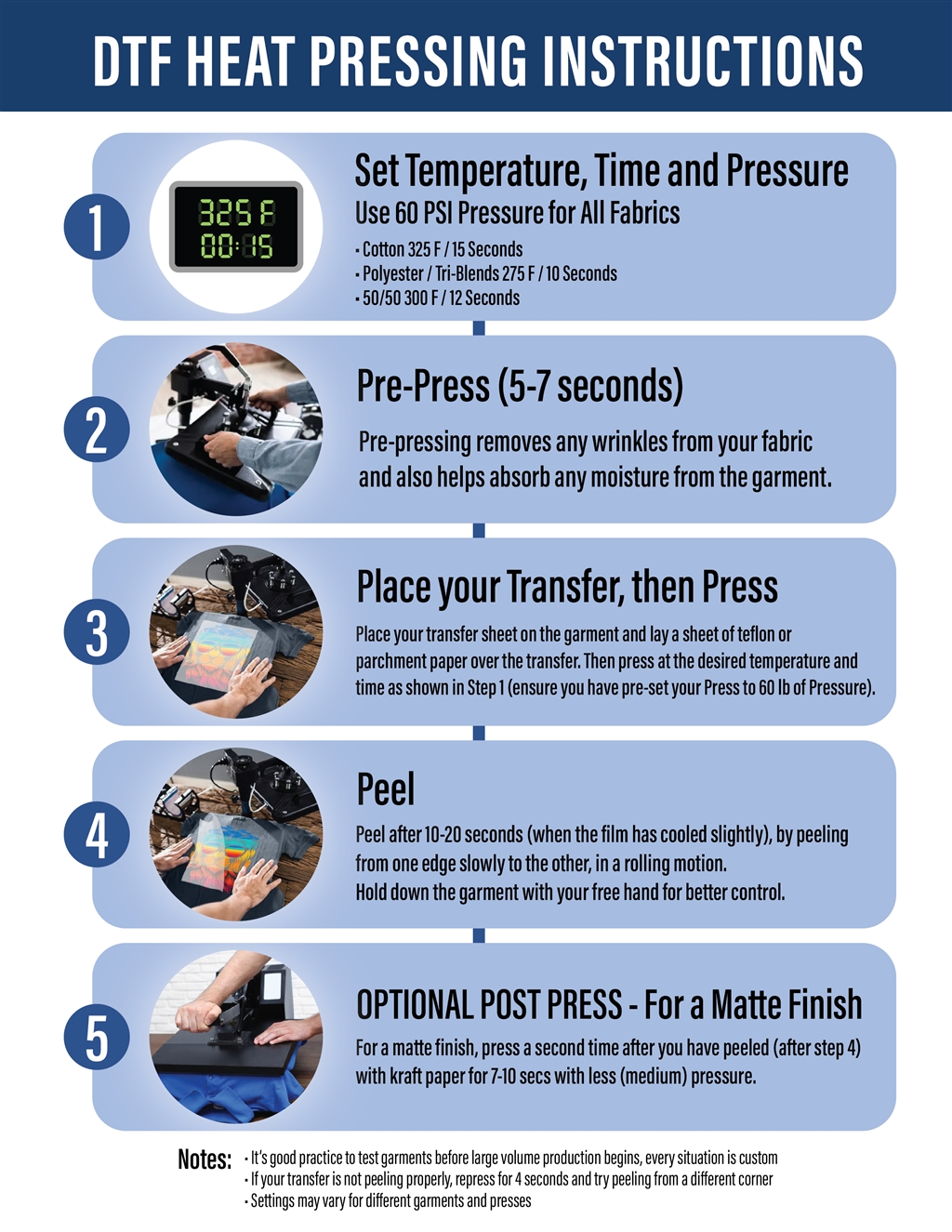

After applying the powder, the film is carefully placed inside a curing oven to melt the powder. Powder melting points usually range between 284 - 338℉ depending on different factors. Once melted, the powder becomes an adhesive that allows the design to stick to the garment. If you don’t have a curing oven, a heat press will also work. Ensure not to press it down onto the film by leaving a ⅛” - ¼” gap between the film and the heat press’ top plate, applying heat without touching the film. Once your powder is melted, apply your transfer to your garment and press. For "JUST IRON, AND DONE" Custom Printed DTF Transfers, each film and powder is different, but with premium matte hot peel film and Premium powder, it is recommended to heat press at about 280 degrees for 12 seconds with medium/heavy pressure, peeling immediately after. This method ensures a seamless iron press transfer to any fabric type.